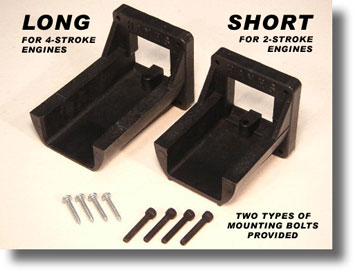

Hayes is not the best known brand and their mounts can be hard to find, but they are a favorite here at BTE.

Hayes mounts are shown on the plans for the Venture 60, Flyin' King, and the Delta Vortex, and we use them in all

of our prototype models. They are lighter than aluminum, and easier to drill.

Hayes is not the best known brand and their mounts can be hard to find, but they are a favorite here at BTE.

Hayes mounts are shown on the plans for the Venture 60, Flyin' King, and the Delta Vortex, and we use them in all

of our prototype models. They are lighter than aluminum, and easier to drill.

You can drill and tap the engine mounting holes and use

the socket-head bolts, or you can drill undersize holes and muscle the sheet metal screws in place. We prefer

the drill-and-tap method at BTE. Note: The 8-32 bolts provided may be too large in diameter for some engines. If

that's the case for you, simply use 6-32 bolts.

|

Beam Width (inside dimension) is 1.690 inches (42.5 mm)

Short Mount Fits: OS .61-.91 SF and FX, Super Tiger .60-.91, K&B .61-.65, Webra .61, HP .61, Enya .60, Rossi .60,

Fox .61-.78, Enya .60-.80

Long Mount Fits: OS .70-.91 Surpass, OS FS81-a FS-95V, Saito .65 .80 .91 1.00

(Note: This mount does not accept the Saito .72 or .82, both of which feature a narrow crankcase.)

|

|

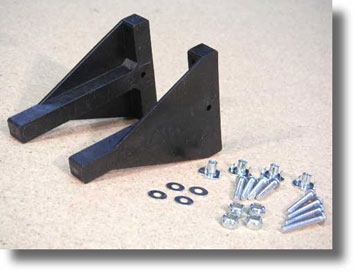

The obvious benefit to using this two-piece engine mount is that it can be spaced to fit any engine crankcase

dimension. It's also a bit lighter than the Hayes mount, but perhaps not quite as stiff. If you have an engine

that doesn't fit the Hayes mount, or you want to save weight (Delta Vortex builders take note!), this may be

the way to go. One other advantage to using this mount is that you can drill your holes oversize and mount

your engine using the supplied bolts with lock nuts installed below the beams. No tapping required!

The obvious benefit to using this two-piece engine mount is that it can be spaced to fit any engine crankcase

dimension. It's also a bit lighter than the Hayes mount, but perhaps not quite as stiff. If you have an engine

that doesn't fit the Hayes mount, or you want to save weight (Delta Vortex builders take note!), this may be

the way to go. One other advantage to using this mount is that you can drill your holes oversize and mount

your engine using the supplied bolts with lock nuts installed below the beams. No tapping required!

|

|

|